TEL:+86-22-58301016

Naphthalene Sulfonate Superplasticizer

Features

● Safety: Non - toxic, Tasteless, Non - combustible, Non - corrosive to steel.

● Water reduction rate:15-25%

● Slump of concrete increase 5-8 times

● Cement dosage reduce 10-25%

● Concrete strength increase 20-60%.

● 28day strength increase 120%.

● Autoclaved concrete autoclaved time reduce 2-3 hours.

● Good compatibility with different kinds cement and concrete admixtures.

● Appearance: Light brown powder

● Solid content: ≥92%

● PH value (5% aqueous solution) : 7-9

● Sodium sulfate content: 3%-19%

● Cement net slurry fluidity: ≥200mm

TJSW® Water Reducer

Water reducer is a kind of concrete admixture that can reduce the amount of water used for mixing under the condition of maintaining the basic constant slump of concrete. Most of the admixtures are anionic surfactants, such as lignin sulfonate naphthalene, sulfonate formaldehyde polymer etc. After adding concrete mixture, it has dispersive effect on cement particles, can improve its workability, reduce water consumption and improve the fluidity of concrete; And reduce usage amount of cement.

We focus on providing high efficiency water reducer for concrete manufacturers,including Naphthalene Water Reducer and Polycarboxylate Superplasticizer.

Features

● Safety: Non - toxic, tasteless, Non - combustible, Non - corrosive to steel.

● Cement net slurry fluidity: ≥200mm

● The slump of concrete can be increased 5-8 times

● The early and late strength of concrete increase by 20-60%.

● Recommended dosage: 0.5~1.0% of cementing material

● Water Reducing Rate:15%~25%

Naphthalene Sulfonate Superplasticizer

● Appearance: Light brown powder

● Solid content: ≥91%

● Sodium sulfate content: 3%-30%

● PH value : 7-9

Usage

| Grade | Solids Content | Sodium Sulfate Content | Chloride Content | Water Reducing Rate |

| FDN-A | >92% | <5% | <0.3% | 18-28% |

| FDN-CC | >91% | <19% | <0.4% | 16-22% |

| FDN-C | >91% | <29% | <0.5% | 15-20% |

Details Information

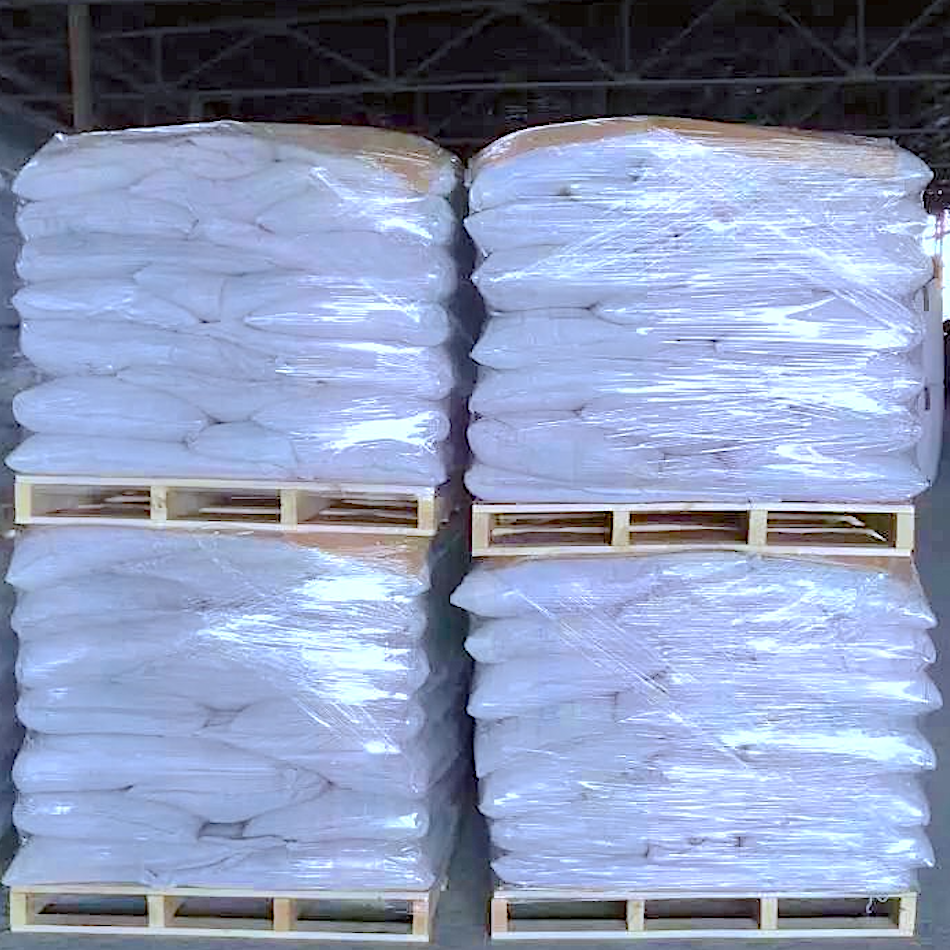

Packing & Shipping

● Waterproof concrete

● High-performance concrete

● Packing in woven bag with plastic inner, Net weight 25kg±0.2kg,50kg±0.2kg,750kg±0.2kg

● Keep in dry, cool and well-ventilated place to avoid direct sunlight or freezing.

● Storage at 0°C to 40°C

Application

● Steam curing concrete

● High mobility concrete

● Pumped concrete

● Prestressed concrete

Polycarboxylate Superplasticizer(Liquid)

● Appearance: Light yellow viscous liquid ·

● Solid Contents: 50.0±1%

● Density: 1.07±0.01 g/mL

● PH value: 7.0±1.0

● Chloride Contents: ≤0.6%

● Alkali Content(based on solids): ≤5.0%

● Sodium Sulphate Content:≤5.0%

● Formaldehyde Content :≤0.05%

Features

● Safety: non - toxic, tasteless, non - combustible, non - corrosive to steel.

● Cement net slurry fluidity: ≥240mm

● The early and late strength of concrete increase by 140-180%

Usage

● Recommended dosage: 0.2~0.8% of cementing material

● Water Reducing Rate:25%~35%

● Do NOT use with naphthalene concrete dispersants simultaneously

Packing & Shipping

● Gushing concrete

● High-performance concrete

Application

● Packing in 200kg drum,1000kg tank ● Keep in cool place to avoid direct sunlight ● Storage at -5°C to 40°C

● High strength durable concrete

● High mobility concrete

● Pumped concrete

● Prestressed concrete

Polycarboxylate Superplasticizer(Powder)

● Appearance:White Powder

● Solid Contents:98±1%

● Density:500±15

● PH value:5-7

● Chloride Contents:≤0.1%

● Alkali Content:≤5.0%

Usage

● Recommended dosage: 0.14~0.25% of cementing material

● Water Reducing Rate:25%~35%

● Do NOT use with naphthalene concrete dispersants simultaneously

| Dosage(%) | Water Reducing Rate(%) |

| 0.14 | 18 |

| 0.18 | 23 |

| 0.20 | 29 |

| 0.22 | 32 |

| 0.25 | 35 |

● High performance ,High strength,High fluidity Concrete

● Dry mortar: Self-leveling mortar; High strength grouting material; Thermal insulation mortar; Ceramic tile adhesive, etc.

Application

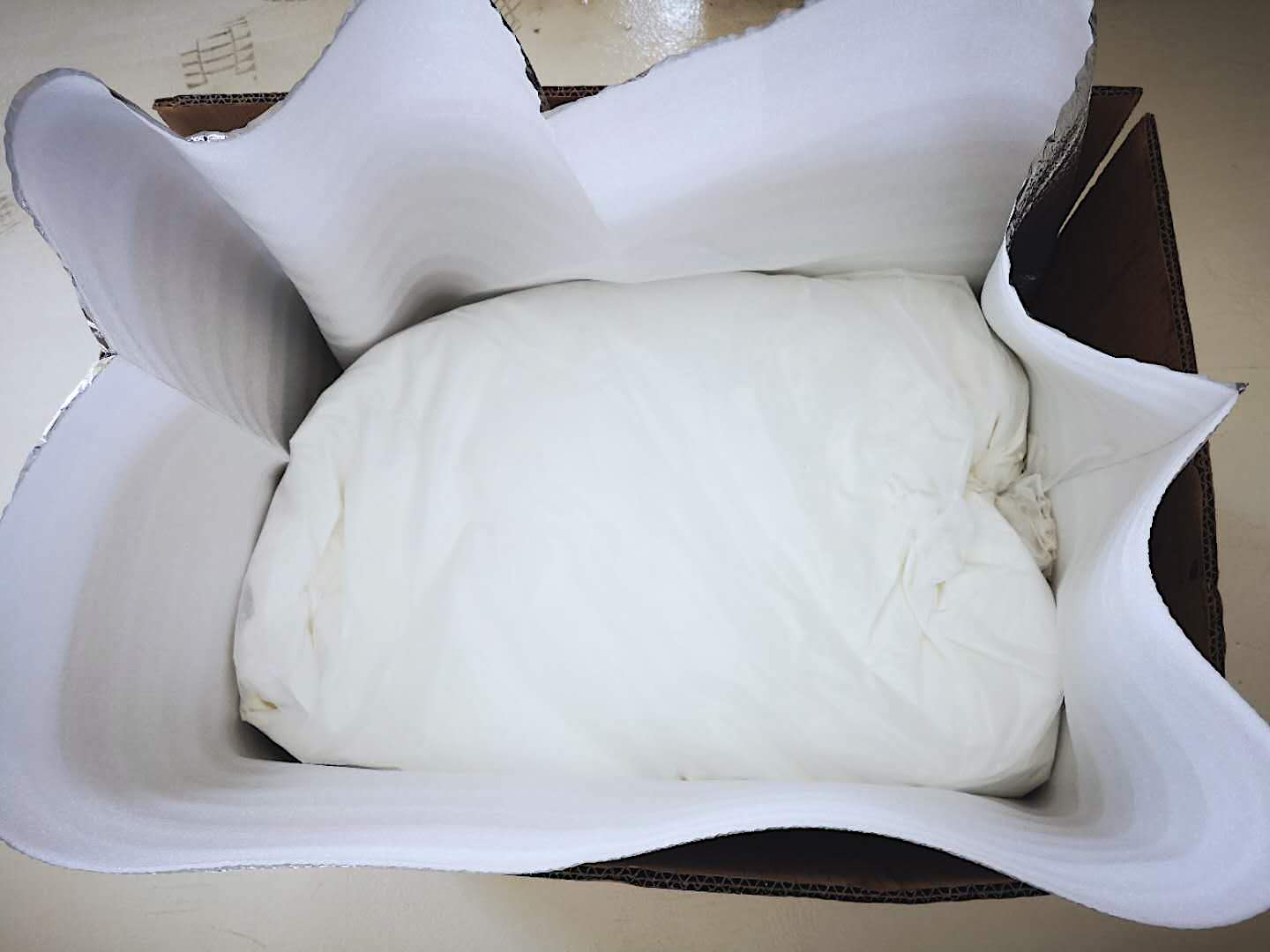

Packing & Shipping

Packing in Paper-Plastic lamination package with PCE inner. Net weight 25kg±0.2kg