TEL:+86-22-58301016

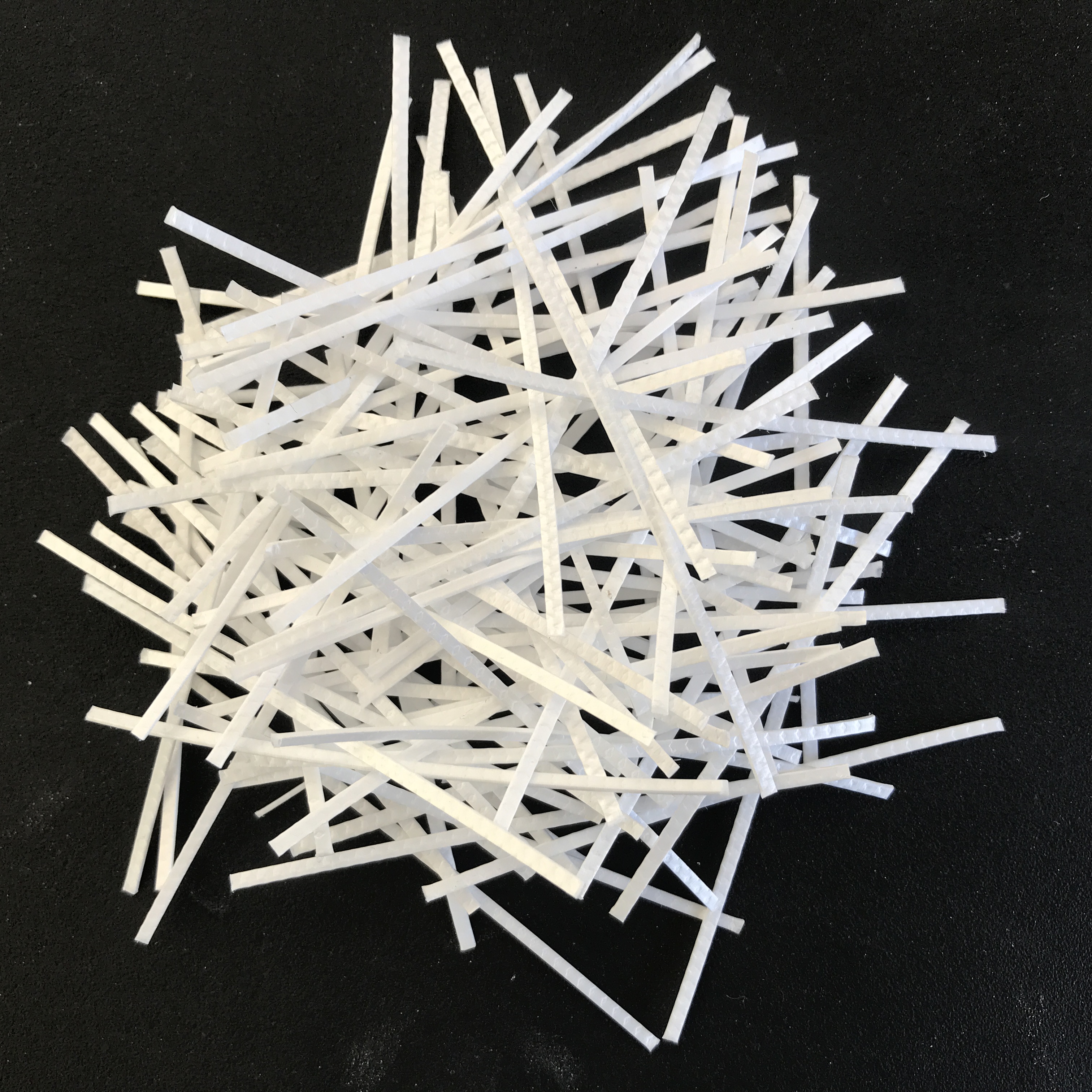

Macro Synthetic Fiber

Applications

● Shotcrete

● Channel and tunnel lining

● Mining

● Precast concrete

● Structural rehabilitation

Benefits

● Provides three-dimensional reinforcement against micro and macro-cracking.

● Provides good impact, fatigue, shrinkage control and ductility in all grade concretes.

● Cost saving, is easier to use, to disperse and safe to handle, reduce equipment wear, fiber rebound and increases build-up thickness compared with steel fibers for shotcrete applications.

● Can be used in highly corrosive circumstance.

● The surface has been embossed, which greatly improves the cohesive force between fibers and concrete, and also boosts shrinkage resistance and crack resistance.

Macro synthetic fiber is made of Polypropylene. It is used as an alternate to steel fibers and welded wire mesh for precast concrete and shotcrete reinforcement applications. Specification for Fiber Reinforced Concrete and Shotcrete, and are specifically used to improve impact, shatter and abrasion resistance, to increase fatigue resistance, to increase toughness of concrete and of provide long term durability of concrete and cement based building products.

Packaging

● 5kg per carton, 1200kg per pallet.

● Special packaging can be supplied on request.

UHPC Special Synthetic Fiber

UHPC special synthetic fiber uses hydrophilic modification technology for its surface treatment. It has excellent dispersibility in UHPC, and has good bonding performance with cement matrix materials, which can effectively reduce and inhibit UHPC plastic shrinkage, drying shrinkage, Micro-cracks caused by temperature changes and other factors significantly improve crack resistance, toughening, impact resistance, fire and explosion resistance of UHPC.

Applications

● Building decoration exterior wall

● UHPC carved artwork

● Cement flower pot products

● Municipal road bricks etc.

Benifits

● No rusty

● Excellent dispersity

● Self compact

● Light and Artistic

● Colourfull

Packaging

● 1kg per biodegradable paper bag

● 10kg per plastic bag or carton

● Special packaging can be supplied on request.

Micro Synthetic Fiber

● Micro - reinforcement system for concrete---100% virgin polypropylene monofilament fibers containing no reprocessed olefin materials. Micro pp fiber is designed to control plastic shinkage and settlement cracking in concrete.

Applications

● Slabs on ground

● Side-walks, driveways, decks, curbs

● Precast elements

● Overlays / toppings

● Tunnel shotcrete

● Roads / Pavements

● Bridge Decks

Benifits

● Reduces plastic shrinkage cracking.

● Improves impact, shatter and abrasion resistance.

● Increases cohesion and reduces segregation.

● Reduces freeze/thaw damage.

● Promotes uniform bleed and reduces bleed water to prolong the life of the building.

● Cost saving, is easier to use, to disperse and safe to handle.

● Can be used in highly corrosive circumstance.

Packaging

● 20kg per plastic bag

● Special packaging can be supplied on request.

Micro Steel Fiber

Micro Steel Fiber are made of copper-coated steel wire. It is one of the most important materials of RPC and UHPC.

Applications

● UHPC Precast components

● Ground, bridge, highway pavements dam

● Railway sleeper

● Shotcrete, tunnel and mine

Benifits

● Good dispersion performance in concrete.

● Less impact on UHPC liquidity.

● Significantly improve the toughness of concrete.

● High compressive strength, tensile strength and elastic modulus

● Provides good impact, fatigue, shrinkage control and ductility in all grade concretes.

Packaging

● 20kg/bag, 1000kg/pallet.

● Other packaging can be supplied on request.

TJSW® Concrete Fiber

● Fibers are an ideal ingredient for use in concrete and mortars as a method for improving these materials where they may otherwise have weaknesses.

● Concrete fibers reduce shrinkage crack formation and crack widths whilst also increasing performance in abrasion resistance and fire resistance. Improve load capacity and ductility and protection against freeze-thaw cycles.

● Additional benefits such as Better cohesion in the fresh concrete, Higher flexural and shear strengths, reduction or elimination of reinforcing steel and increased durability etc.